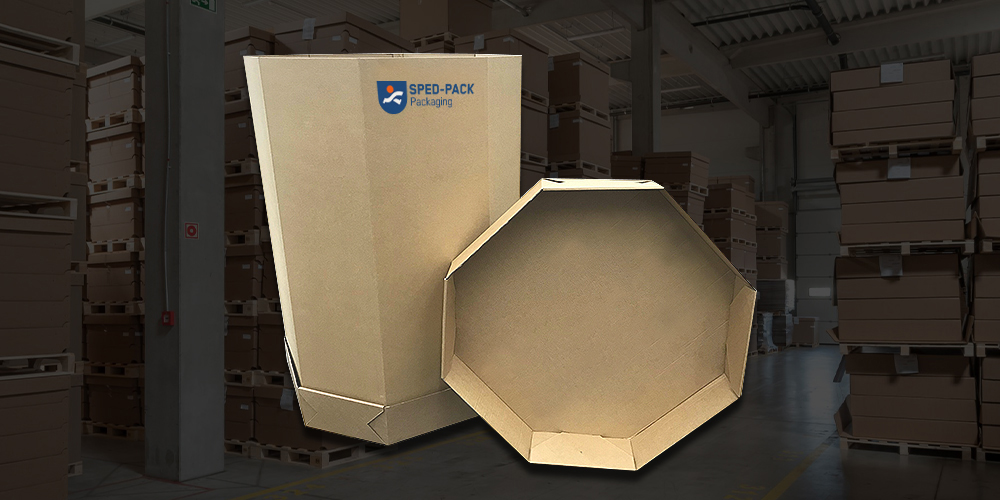

Octabin

What is Octabin?

Octabins are designed for heavy duty. Thanks to their eight corners, they can carry much more weight than their rectangular counterparts, because the corners are under less load. They are preferably used for large masses of granules,

bulk goods or coiled metal wire, because they are stable, space-saving and can be stacked.

Are you interested in our services?

The octabins can be designed to meet specific requirements and can be manufactured in custom sizes, for which we can also manufacture custom pallets.

The octabin can be regular, irregular, pallet-sized or even telescopic.

We make every idea a reality.

The octagonal boxes are mainly made of 7-ply corrugated cardboard due to the high load-bearing capacity. Thanks to our digital printing facility, it is also possible to print these boxes made of thick material.

The finished octabins are sent to our partners in a flat pack, thus reducing transport costs.

Octabine properties

– high load capacity

– high tensile strength

– resistance to load and internal pressure

– stackable

– better filling ratio due to its shape

– resistant, also suitable for overseas transport

– made of corrugated cardboard and therefore recyclable and environmentally friendly

– ensures cost-effective transport

Applications of octabins

– automotive industry

– pharmaceutical industry

– chemical industry

Thickness of octabins

– Coating: 5 layers or 7 layers

– Substrate + roof: 3 layers or 5 layers

Load capacity of octabins

– depending on base material and stack height, but from ~500 kg to ~1000-1500 kg

Sustainability of octabins

Made from corrugated cardboard and therefore recyclable, it is a good substitute for other types of packaging

in an effort to be environmentally friendly.